Here is the honing procedure I use a good hone is a must.

I use a lot softer stones then most guys honing out there, The biggest trick to honing is to use the least amount of pressure to get the job done which reduces the heat build up and the other advantage is less cylinder flexing with less feed pressure.

The last .004 I use the 412 stones in and take out .001 at a time to keep the heat to a minimum the last .001 I go to the 512 stones down to the .0005 the last .0005 I go to the 623 stone. To plateau hone I use the C30-CO3-81 stone on OEM blocks I use 4 strokes and the harder blocks I go 6 strokes.

Different blocks may require different feed pressures for the proper finish.

I build a lot of endurance engines (circle track) and a 400 finish does not work very well in these applications as some engines now I don't see for 2 or three years.

Been over my honing procedure with Matt at Total seal he says its spot on.

So far never had any complaints with what I have sent out the door for cylinder wall finish and its been tested many years now and proven.

I really enjoy when guys tell me they can do the same thing with there servo quip hones

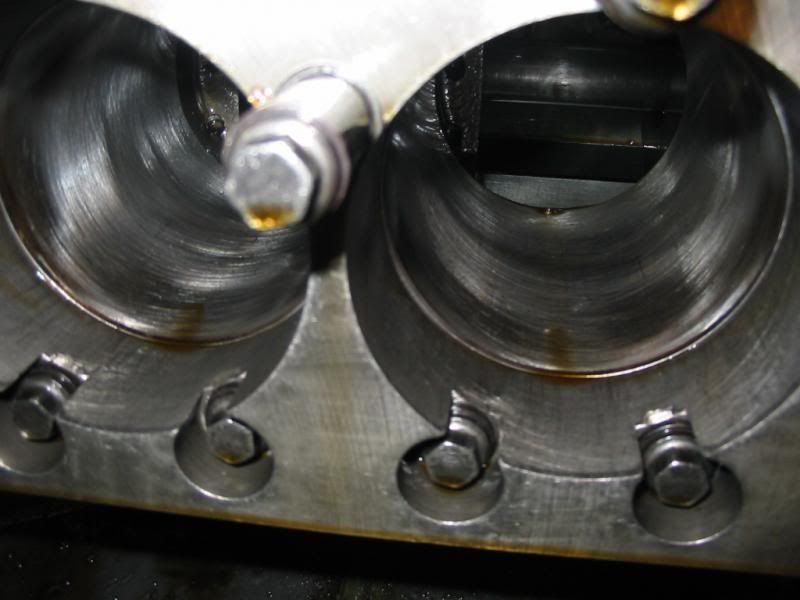

Here is a thread from another site on plate honing you can see the shadows und the bolt holes and the cylinders measured .004 distortion.

Quote:

|

Originally Posted by CNC BLOCKS

This a perfect example of why plate honing is a m must along with using a good hone.

This engine is a 604 GM crate circle track engine I think this block was honed once as the bores were 4.0015 Had an old time racer 78 years old that raced for many years witness this and was amazed.

This class can only go with a custom .005 over piston made by Mahle, After bolting the plate on and making a couple of strokes with the 412 stones it was clear that there was a reason the ring land between the 1st and 2and ring shows signs of carbon or poor ring seal. There was .004 distortion form Low to high

You wouldn't see as much distortion with a Bowtie, Dart or World block, But I will say the getting close or at max bore on one these block you will see distortion. It does make a difference studs VS bolts. |