|

|

|

#21 | |

|

Junior Member

Join Date: Jan 2004

Posts: 87

Likes: 39

Liked 166 Times in 47 Posts

|

Quote:

I do a lot of welding and fabrication. If the steel was sourced offshore, then it's not ideal. That's not to say that domestic steel wouldn't have bent, but I doubt it would have to the degree seen in the photos. All of the offshore steel that I have used is substandard at best. You can tell immediately when you hit it with the tig torch.

__________________

SS/BS 1921 |

|

|

|

|

|

|

#22 | |

|

Member

Join Date: Aug 2010

Location: CT

Posts: 384

Likes: 1,254

Liked 247 Times in 106 Posts

|

Quote:

Can't argue about quality of the steel, I agree. But, if the front (with any material) isn't bending, then it leads me to wonder if the rear is moving up or down (instead of fore and aft) on the hard landings - crossmember possibly flexing would sort of "pivot" on the front support and help to bend the midplate? Tossing ideas out here because if nothing is moving, nothing can bend, I don't care what material it's constructed from.

__________________

Phil Molski S/C 1623 |

|

|

|

|

|

|

#23 | |

|

Junior Member

Join Date: Jan 2004

Posts: 87

Likes: 39

Liked 166 Times in 47 Posts

|

Quote:

__________________

SS/BS 1921 |

|

|

|

|

|

|

#24 |

|

Junior Member

Join Date: Apr 2016

Posts: 54

Likes: 1

Liked 14 Times in 11 Posts

|

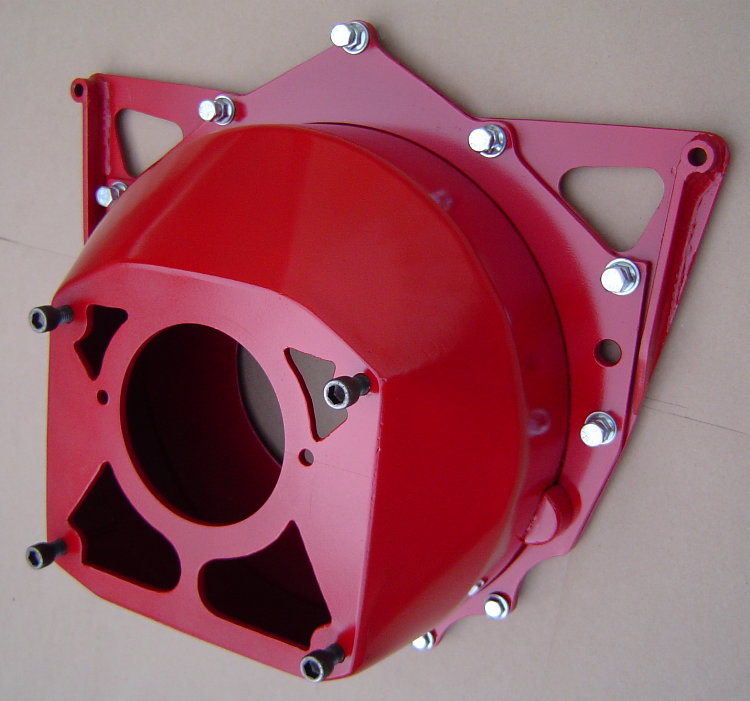

Not a Mustang or Super Stocker, but here's something I made for one of my personal hotrods. It's a 3pc setup where the bell, block plate, and midplate are all separate pieces. This gives me the additional option of removing the complete engine/flywheel/clutch as an assembly without having to disturb the trans/driveshaft/shifter. Having the support ears "up" rather than "out" keeps them completely away from the headers. In this pic you can also see three added bolts that serve to keep the bell attached to the midplate when the bellhousing bolts are removed...

The car does have a crossmember under the rear of the trans, but it serves more as lower support and fore/aft travel limiter, it does not bolt to the trans itself. Here's a pic of the block plate installed on the engine, I made the center hole bigger to aid clutch cooling...  Here's a pic from the inside showing one of the aluminum brackets I made to spread the loads across a wider area of the car's thin sheetmetal firewall...  Like I said this is not a Mustang, but it is similar in that it is a unibody car. This car has had the midplate attached to the firewall for 12 years now, no problems.  Here's a link to some info about the rest of the car, there are some pictures on there that document my process of fabricating this bellhousing from scratch... http://grannys.tripod.com/20102.html

__________________

Grant website- http://ClutchTamer.com We make your non-adjustable clutch...ADJUSTABLE! |

|

|

|

|

«

Previous Thread

|

Next Thread

»

|

|

All times are GMT -4. The time now is 07:02 AM.

Linear Mode

Linear Mode