|

|

|

|

#471 |

|

Member

Join Date: Mar 2005

Location: Jersey

Posts: 359

Likes: 35

Liked 204 Times in 54 Posts

|

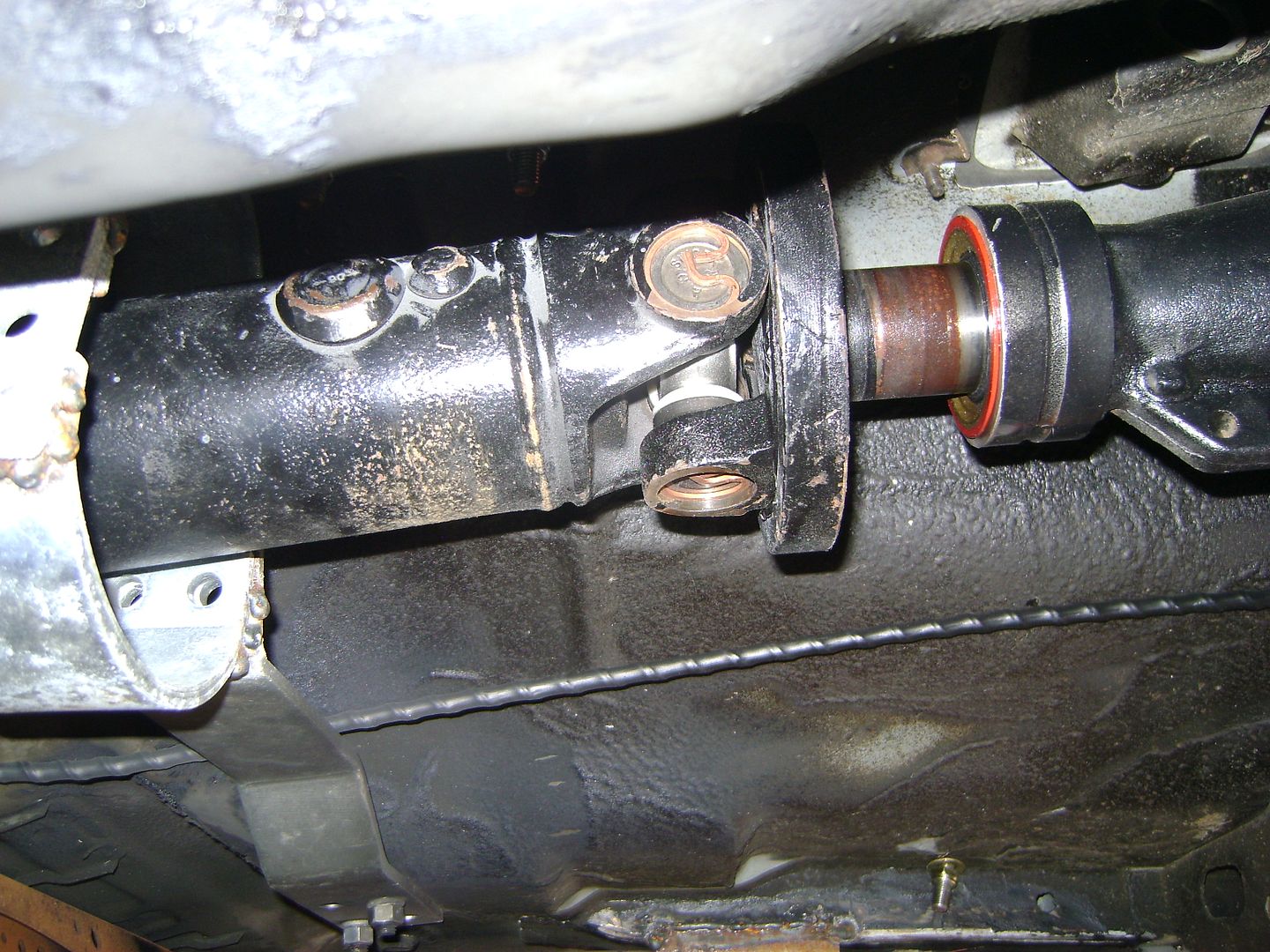

Is it an illusion, or has the u-joint moved? It looks like it's not fully seated to the end of the bore on that yoke (bottom bore in this picture). |

|

|

|

|

|

#472 |

|

VIP Member

Join Date: Oct 2013

Location: Gulf Breeze, FL

Posts: 1,651

Likes: 8

Liked 33 Times in 16 Posts

|

I'll look at it close today, but if you view the rear it has about the same appearance.

Edit : U-joints are fine.

__________________

Rich Taylor I/SA - 321 Last edited by HandOverFist; 05-12-2015 at 01:51 PM. |

|

|

|

|

|

#473 |

|

VIP Member

Join Date: Oct 2013

Location: Gulf Breeze, FL

Posts: 1,651

Likes: 8

Liked 33 Times in 16 Posts

|

Failing to find anything of significance thus far I feel its time for a large move to test for effect. I have either missed the mark on the engine assembly or the fuel events are way off. Thinking of removing the aftermarket controller and letting the factory ecu do it's thing...I can adjust the fuel pressure and monitor the wide band O2 readings.

__________________

Rich Taylor I/SA - 321 |

|

|

|

|

|

#474 |

|

Member

Join Date: Mar 2005

Location: Jersey

Posts: 359

Likes: 35

Liked 204 Times in 54 Posts

|

Don't do that. You'll hit the rev limiter, and not be happy.

It's your first time out. Leak the motor and adjust the valves, then bring it to test and tune. Make 10 hits, make one change at a time, and log the changes. It sounds a bit sluggish out of the hole. You may need to give it more timing. Let the engine and trans find their way. Don't be afraid to lower the shift points. What did you install the cam at? Most importantly, talk to John Pressing. He went 11.50 in L/S I believe 10 years ago in one of those cars. There are lots of guys with good experience on this board, but from my point of view John's the guy you want to talk to. Last edited by SSGT Mustang; 05-12-2015 at 10:06 PM. |

|

|

|

|

|

#475 |

|

VIP Member

Join Date: Oct 2013

Location: Gulf Breeze, FL

Posts: 1,651

Likes: 8

Liked 33 Times in 16 Posts

|

Working my way from back to front I found an interesting item today. My TPS sensor is only registering a maximum of 92 percent WOT. Rounded a new one up and will test it tm...if that knocks another 3 tenths off it will be the best $35 I have spent in awhile.

__________________

Rich Taylor I/SA - 321 Last edited by HandOverFist; 05-14-2015 at 01:21 AM. |

|

|

|

|

|

#476 |

|

VIP Member

Join Date: Oct 2013

Location: Gulf Breeze, FL

Posts: 1,651

Likes: 8

Liked 33 Times in 16 Posts

|

No joy with the new TPS sensor...best I can achieve is 94% throttle. Must be a voltage thing and I don't know how I would allow/adjust for that. There is a variance scale screen in the handheld for TPS set-up, but I have not been able to get it to move one way or another.

__________________

Rich Taylor I/SA - 321 |

|

|

|

|

|

#477 |

|

Member

Join Date: Nov 2011

Posts: 264

Likes: 42

Liked 61 Times in 25 Posts

|

When you move the sensor on it's adjustment screws, it doesn't change on your multimeter? Also, what is your multmeter reading with the throttle closed?

Last edited by Tony Corley; 05-15-2015 at 05:30 PM. |

|

|

|

|

|

#478 | |

|

VIP Member

Join Date: Oct 2013

Location: Gulf Breeze, FL

Posts: 1,651

Likes: 8

Liked 33 Times in 16 Posts

|

Quote:

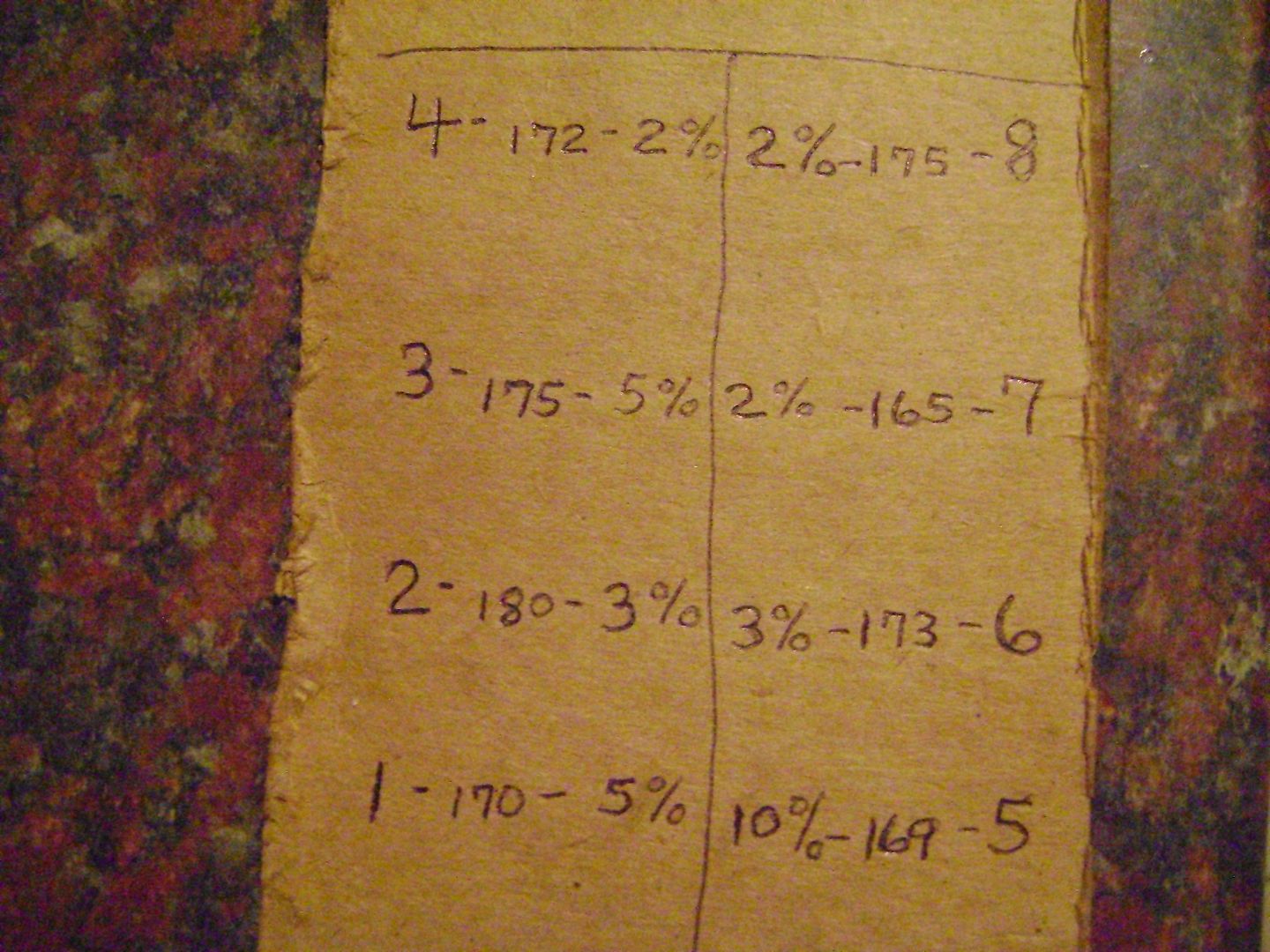

Did a compression and leakdown test on all cylinders today...I'm satisfied with the results. These figures were on a stone cold engine btw.  Took the night off from work so I could go to the track and try to make something happen. Turned out to be a wasted effort as it spun the tires badly every pass. I thought these DOT radials would be ok for initial testing, but I now see it is going to require a set of slicks.

__________________

Rich Taylor I/SA - 321 |

|

|

|

|

|

|

#479 |

|

Member

Join Date: Nov 2011

Posts: 264

Likes: 42

Liked 61 Times in 25 Posts

|

Set the TPS first , and make certain it is giving out the correct readings on a multimeter, then make the changes with the PMS. Since it's easier to paste and copy, I took this straight from Anderson's website.

To start off with lets set the throttle position sensor, so the PMS is on the right load tables Warm the car up to operating temperature (180-198) do this with a drive. Don’t just let it sit and idle. Set your base idle (with the idle motor unplugged) at 850-900 rpm with the throttle screw. Now shut the car off, turn key to on position and check your T.P. sensor voltage with a volt meter. Take that voltage ( lets say it is 1.04 volts) and go into the PMS option to TPS voltage and set idle voltage to 1.06. Now turn off key and turn it back on. It should say idle now on the data screen. If not readjust voltage numbers till it does. Next put throttle pedal to the floor and make sure PMS says WOT in data screen. If not adjust WOT T.P. sensor voltage until it does. This gets the PMS in sinc with the load table. Last edited by Tony Corley; 05-16-2015 at 06:00 AM. |

|

|

|

|

|

#480 | |

|

VIP Member

Join Date: Oct 2013

Location: Gulf Breeze, FL

Posts: 1,651

Likes: 8

Liked 33 Times in 16 Posts

|

Quote:

Interesting article on the subject here... http://www.w8ji.com/mustang_throttle...ion_sensor.htm

__________________

Rich Taylor I/SA - 321 Last edited by HandOverFist; 05-16-2015 at 09:49 AM. |

|

|

|

|

|

|

|