|

|

|

|

|

|

#1 |

|

Junior Member

Join Date: Mar 2008

Posts: 73

Likes: 0

Liked 0 Times in 0 Posts

|

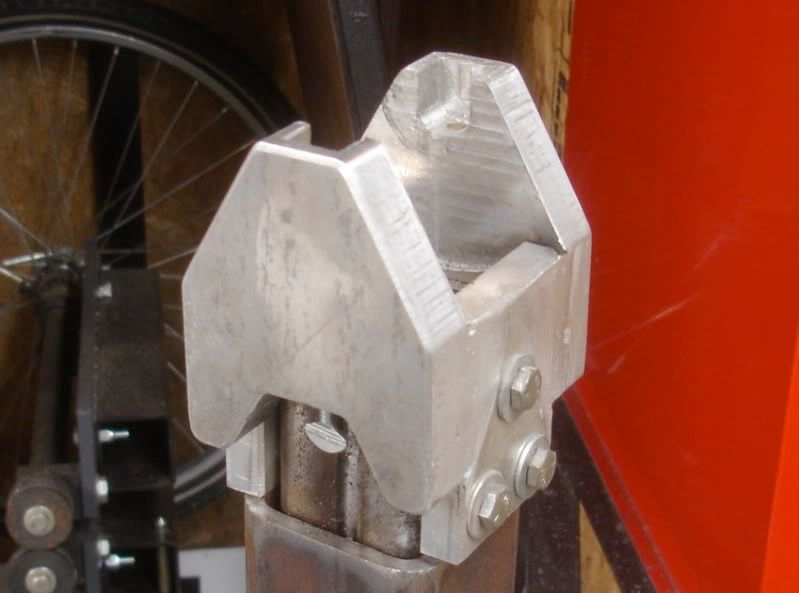

So, I had some time this weekend & I decided I'd get the hose & clamp set-up replaced. I pulled out the old slab of aluminum and started whittlin' away.  Flipped one over & cut an o-ring groove  cleaned them up on the lathe & cut the mating surfaces for a nice air tight fit.  Finished and ready to install. |

|

|

|

|

|

#2 |

|

Junior Member

Join Date: Mar 2008

Posts: 73

Likes: 0

Liked 0 Times in 0 Posts

|

My aluminum welding skills aren't the best, but I got 'em melted together.  Intercooler side with o-ring  all bolted together and back in the caah.  dash cover back in. No more hose & clamps. I feel safer with this set-up by my shin. I've seen some ugly footage of those clamps letting go. That's what I did this weekend. |

|

|

|

|

|

#3 |

|

VIP Member

Join Date: Jun 2002

Location: New Holland, PA Mooresville,NC

Posts: 1,163

Likes: 245

Liked 16 Times in 11 Posts

|

You have a real talent, you should pursue it in some way. your having fun doing it. Why not make $$ while doing it. Good luck with the rest of your project. Best Regards

__________________

Bob Pagano A/SA |

|

|

|

|

|

#4 |

|

Junior Member

Join Date: Mar 2008

Posts: 73

Likes: 0

Liked 0 Times in 0 Posts

|

Thanks Bob.

I have a one man sign shop that keeps me pretty busy & is something I like to do also. The fab work is a nice change of pace.*Something to do to relax on those rare occasions when I have nothing to do. |

|

|

|

|

|

#5 |

|

Junior Member

Join Date: Mar 2008

Posts: 73

Likes: 0

Liked 0 Times in 0 Posts

|

I had a couple hours yesterday afternoon & a couple more this afternoon, so I thought I'd get organized for the upcoming "Z" firewall build. I've got some sheet metal tools that have been under the bench for a good long while now. So, I chopped up an old attachment I had for my first track loader that was just collecting dust in the corner. It had some slip tubes on it (like a receiver for the hitch). I used some angle iron I had in the shed and made this deal up. I put it on an outside corner of the shop so I'd have plenty of workin' room.

å åI bought a stretcher/shrinker at a car show a couple years ago. No mount so it hasn't been used yet.  Harbor Freight Planishing hammer. Might call it new old stock. I've had it for a long time too, but never used it.   I've used the bead roller a couple times. Clamped it in the band saw when I DID use it.  I'm wondering about a wing (table top) on each side of the bead roller to help feed the stock through? or maybe it would just get in the way? Any thoughts? I still plan to make an attachment to hold the bench vise, and one for a small welding table. I'm gettin' tired of saw horses.........  ops: ops:that's what I've been up to this weekend. |

|

|

|

|

|

#6 |

|

Junior Member

Join Date: Mar 2008

Posts: 73

Likes: 0

Liked 0 Times in 0 Posts

|

I welded up the welding table tonight. I cut the supplies kinda' close. I have 1/2 pc. of filler rod left, 20 PSI of argon in the second tank & the 20''x20'' table top was the biggest pc. I could get out of what's left of a 4'x4'x3/16'' sheet of steel.

Bracing under the table. Gettin' low on that stuff too, but I got er' done.

|

|

|

|

|

|

#7 |

|

Junior Member

Join Date: Mar 2008

Posts: 73

Likes: 0

Liked 0 Times in 0 Posts

|

Worked on the bead roller today. I got rid of the hand crank and put a bicycle wheel in its place. Local bike shop gave it to me, it's a little bent, but it works for this deal. I figured the bigger the wheel the better control. I had to try it out, works a whole lot better now. . I made an aluminum table for the exit side. Loosen 1 thumb screw at the bottom and it lifts off a couple pins on the top. I scribed some lines every 2" as guides. no fence yet. I think I'll use it this way first and add a fence later.

Got the Vice mount done. I made a knee brace for those times when I feel the need to beat on the vise. Same brace will work on all the attachments.  ....and I got the rack finished up tonight. Everything in easy reach, tucked away behind the door. Oh, I bent up some scrap sign aluminum also, to protect the wall.  I think I'm ready to start on the "Z" firewall now. I have to put a quick disconnect in the planishing hammer air line so I don't have to drag the foot pedal around. It's a pain in the hose this way. |

|

|

|

|

|

#8 |

|

Junior Member

Join Date: Mar 2008

Posts: 73

Likes: 0

Liked 0 Times in 0 Posts

|

Before I start the firewall I wanted to get the English Wheel built. Ran into a little snag though. I made up the bottom anvil assembly last night. Cut the frame parts out today. Got a couple pcs. clamped together to weld.......and then stripped the threads out of the torch head on the TIG. and it's saturday.

There goes the weekend. ...............

|

|

|

|

|

| Thread Tools | |

| Display Modes | |

|

|