Dennis and I began the process of installing a Coyote 5.0 liter engine in his 1990 T-Bird in Late December of 2019.

His T-Bird, just like mine utilized a 351 Cleveland engine for many years. I converted my 1996 T-Bird to Coyote power in 2012.

Since both of these cars were built by Dennis and myself back in the mid 1990s, they were both very similar. We decided it was

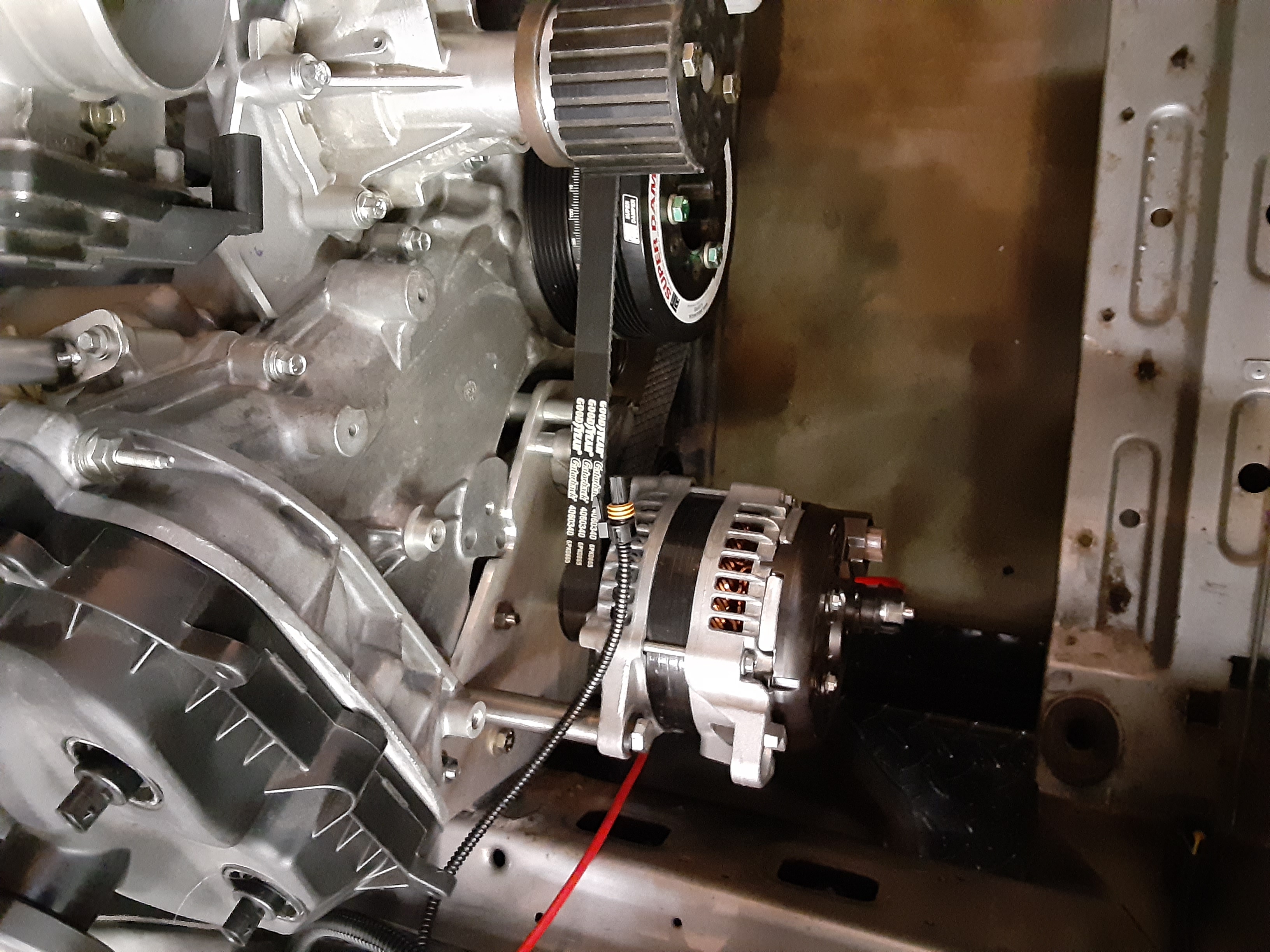

easier to just remove and duplicate all of the "Coyote" unique parts from my T-Bird. This included the 2 piece motor plates,

the step headers, the mid plate, modifications to the transmission cross member, electric water pump drive bracket and

alternator bracket. We were off to a good start, but the pandemic slowed us down since I had to work on the T-Bird by myself

for about six weeks. In the mean time Jimmy Ronzello (JRP) was assembling the race engine for the T-Bird and Joel (Joel's on Joy)

was building the C4 transmission. The engine and transmission were dropped off at my shop at the end of April. I installed the

engine and transmission, but I still need to make up the EFI wiring harness and re-wire the T-Bird. We finally finished up the

in late May and were able to go out and test on May 30th. We had drive by wire issues that kept disabling the throttle.

We were only able to get one run partial run under full throttle. We changed out the drive by wire pedal and the drive by wire

throttle body and went to test again on June 7th. We made several full throttle runs and then decided to swap one of the two

components in question back. We chose to swap back the throttle body since it was a lot easier to change then crawling up

under the dash and changing the throttle pedal. We went to make another test run and again after we did the burnout the

throttle went into limp mode. This time we did not shut off the main power and I was able to connect my code reader and

determine that ECU was throwing a code that said the throttle blade was sticking. I then realized that we were probably

getting too much heat in the throttle body since we had an aluminum aftermarket intake manifold on the engine. In fact I

realize that I had to use gloves to handle the hot throttle body when changing it earlier. That was it for the day so we did

not make any more runs. For our next test session Dennis fabricated a nylon plastic spacer to go between the aluminum intake

and throttle body. Dennis also fabricated an adapter so we could use the 80 mm throttle body on a Coyote Voodoo intake manifold.

This is the intake that comes on a Shelby GT-350 5.2 engine. It uses a 90 mm throttle body, therefore the need for an adapter.

At our next test session in August we found that the Voodoo intake was faster that the fabricated aluminum intake

manifold that we started out with. I had also used that aluminum intake on my 96 Mustang GT/G car and had never had a chance to try

anything else, but was always skeptical about it. Our last test session for 2020 was in October and we went 10.92 at 125 miles per hour.

For 2021 we will change to radial tires and optimize the rear gear ratio for the rollout. The engine in this car is very basic.

It has stock camshafts and VCTs. It uses an OEM ECU and I use SCT software to modify the calibration. Dennis will start off by

racing this car in 2021 at NMCA events and Great Lakes Stock Super Stock events. Over time we will work with this engine as is

and focus on tuning. Eventually we will get a Holley ECU, lockout the VCTs and replace the stock camshafts with aftermarket

camshafts.

More photos at:

http://9500rpm.com/FGTMTBird/index.html

In car video from US 131 Motorsports Park on October 17th 2020.[/QUOTE]