|

|

|

#41 |

|

Member

Join Date: Aug 2010

Posts: 204

Likes: 2

Liked 57 Times in 23 Posts

|

launch rpm, depends on track bite, and power, marginal tracks require less rpm, different tire press, etc, like rory says, takes seat time and testing to find what it likes or dislikes, i've never seen any charts about rpm, at launch versus rpm in traps, we launch at 6000, shift at 6500, traps is 7400 seems to be best setup, for us.

|

|

|

|

|

|

#42 | |

|

Junior Member

Join Date: Apr 2016

Posts: 54

Likes: 1

Liked 18 Times in 15 Posts

|

Quote:

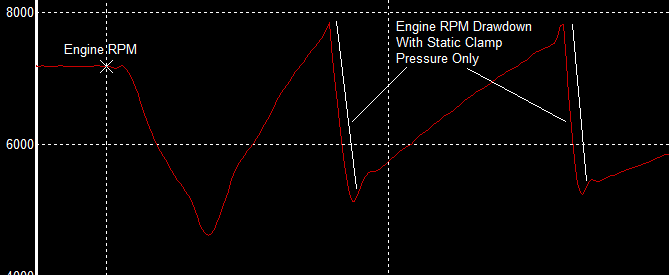

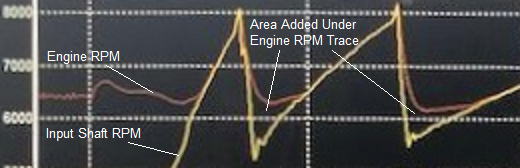

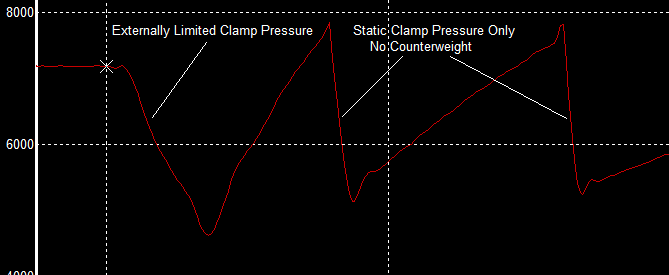

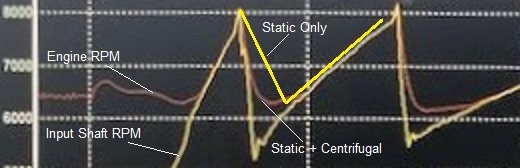

Torque x RPM, highest average number wins if you can get all that power to the track consistently. Raising launch rpm adds area under the engine's rpm trace, which means the engine will produce more power strokes in that critical first second after launch. The clutch's engagement characteristics are among the most important adjustments you can make to a stick shift drag car, both for the launch as well as after the shifts. If you have a typical diaphragm, B&B, or non-adjustable Long style pressure plate that uses spring pressure only (no centrifugal assist), the engine rpm drawdown part of the engine rpm trace will be pretty linear, basically a straight line like on this graph below...  If you have a SoftLok style "adjustable slipper clutch" that uses counterweights in addition to spring pressure to clamp the disc, the part of the engine rpm trace where that clutch pulls the engine down will form a gradual curve. Because its centrifugal counterweight component relaxes as the clutch pulls engine rpm down, overall clutch clamp pressure relaxes as well. Note that engine rpm initially drops very quickly after the gear change (trace falls almost straight down), but then the trace begins to gradually curve as the clutch gradually loses it's ability to pull the engine down any further...  One feature of the curved engine rpm drawdown shape is that it adds area under the engine's rpm trace. If the above clutch had not slipped at all after the 1/2 shift, the ratio change dictates it would have pulled the engine down to around 5245rpm (input shaft speed) after the tires hooked back up. But because it was a SoftLok style clutch with a centrifugal component, clamp pressure relaxed as the engine lost rpm, which in-turn slowed down the rpm loss. Because the car was also gaining speed while the clutch was slipping, the delayed lockup point raised the minimum rpm after the shift to 6302 instead of drawing the engine all the way down to 5245rpm as predicted by the ratio change. That added clutch slip time tightened up the engine rpm operating band, which in-turn allows the engine to operate higher on the plateau of its HP curve. Going back to the static-only (no centrifugal assist) clutch graph below, another thing to note is that you can adjust the angle of engine rpm drawdown on the graph by adjusting the clutch's static clamp pressure. Note that angle of the drawdown after both shifts on the below graph are basically the same, while the drawdown angle after launch is still straight but the rpm is drawn out over a longer time period...  The above difference in drawdown angles was made possible by externally controlling throwout bearing position during launch. Basically the throw-out bearing was not allowed to fully retract during launch, which prevented the full force of the clutch's spring pressure from clamping the disc. The throw-out bearing was then allowed to retract shortly after launch, which in-turn increased the clutch clamp pressure available for the shifts. The angle of the drawdown during launch is adjusted via throw-out bearing position, the angle of the drawdown after the shifts is adjusted via static clamp pressure. You end up with more clutch slip during launch, less clutch slip after the shifts. Here's the SoftLok style curved drawdown shape compared to a straight drawdown after the shifts...  Notice how an adjustable static-only (no centrifugal assist) straight-line drawdown can be optimized to add even more area under the engine's rpm trace than the traditional SoftLok style curved drawdown. Also note that the initial draw down after the shift is not as steep. That flatter angle indicates energy is leaving the engine's rotating assy at a slower rate, which in-turn makes it easier to keep the tires stuck thru the shift. Because the engine is producing power at a quicker rate during the straight-line drawdown, clutch lockup occurs sooner which allows the engine to get a head start on its climb to the next shift point. When you add external throw-out bearing position control to the static only (no centrifugal assist) straight-line drawdown, you end up with a more consistent dead-hook launch that doesn't drag the engine down. It also really shines on a crappy track. The dead hook reduces the need to adjust tire pressure and launch rpm for the purpose of controlling wheelspeed. Without the need to control wheelspeed, you will likely be able to make use of less first gear ratio, which will in-turn allow tightening up the gear splits. Little gains here and there, but it all adds up. It's a lot like the quick automatic transmission cars. A less efficient coupling allows the engine launch higher and gain rpm faster while also reducing rpm loss after the shifts. The increase in power production shows up as more area under the engine rpm trace, and that added power more than offsets the loss of mechanical efficiency. In my opinion, in most cases the traditional SoftLok "adjustable slipper clutch" style clutch tune is becoming out-dated tech. First it limits your ability to take advantage of launch rpm, then it has a tendency to knock the tires loose after the shifts. Knocking the tires loose after the shifts is usually what prevents guys from making the switch to radials.

__________________

Grant website- http://ClutchTamer.com We make your non-adjustable clutch...ADJUSTABLE! Last edited by weedburner; 10-17-2022 at 02:12 PM. |

|

|

|

|

| Liked |

|

|

#43 | |

|

Member

Join Date: Jul 2006

Location: Kansas City

Posts: 398

Likes: 110

Liked 107 Times in 34 Posts

|

Quote:

Clutch tamer is not legal on a Stocker, asked Bob Blackwell about it before he retired. |

|

|

|

|

| Liked |

|

|

#44 |

|

VIP Member

Join Date: Nov 2001

Location: The Lowcountry.

Posts: 2,664

Likes: 2,172

Liked 2,154 Times in 786 Posts

|

Check out Troy's website. Good stuff for sure.

|

|

|

|

| Liked |

|

|

#45 |

|

Member

Join Date: Dec 2010

Posts: 292

Likes: 2

Liked 27 Times in 20 Posts

|

I find it best for me to leave at 4600, and the rpms go down and the car leaves. At that point the clutch is slipping and then locks. The motor really don't have power, so the clutch won't slip, and the the clutch stays locked up till the rpms drop below 4600, on the gear change. I run a lenco, you have to make sure you finish on you disc is fresh. Clutch glazing can give you head aches. Know what a glazed disc looks like

|

|

|

|

| Liked |

|

|

#46 |

|

Member

Join Date: Jun 2007

Posts: 367

Likes: 586

Liked 377 Times in 87 Posts

|

Maybe out of left field here since I worked on very adjustable pro stock clutches. But there is a truth (for me) that applies to all stick cars. The engine must always be ahead of the car. A lot of the people I worked with found that difficult to grasp or maybe I didn't explain it in a way that made sense to them.

Consider a dead hook. The engine is singing and wanting to accelerate. But then you throw the entire weight of the car on it and it simply sags (bogs) under that load. What you're looking for is the engine bringing the car along with it - the clutch comes in within the engine's torque ability and the engine is revving hard, bringing the car along with it. Wheelspeed is critical. Stockers and SS have limited ways to do this. Leave RPM, tires, disk compound, spring weight can all fine tune the load your engine sees at any given part of the run. The lengthy post above this is saying the same thing. The only improvement I'd suggest is bringing the clutch back in quicker after a gear change. If you see the RPM drop as that happens, you've gone too far. And sometimes it's effective for the tires to spin on the change as it keeps both the rpm and the wheelspeed high. It's just my way of thinking which won a lot of rounds. Pulling the engine down out of its range at the bottom of a gear is always slower than a small spike which allows the engine to take off again while letting the clutch catch up to it quickly. Last edited by Dan Bennett; 06-05-2024 at 02:37 PM. |

|

|

|

| Liked |

|

|

#47 |

|

VIP Member

Join Date: Dec 2001

Location: Texarkana Ark/TX

Posts: 2,363

Likes: 454

Liked 693 Times in 269 Posts

|

IMO a lot of the stick cars run too much tire.

__________________

Adger Smith (Former SS) |

|

|

|

| Liked |

|

|

#48 |

|

Junior Member

Join Date: Nov 2002

Location: Nebraska

Posts: 29

Likes: 3

Liked 0 Times in 0 Posts

|

|

|

|

|

|

«

Previous Thread

|

Next Thread

»

|

|

All times are GMT -4. The time now is 08:16 AM.

Linear Mode

Linear Mode