|

|

|

|

#1 |

|

Member

Join Date: Oct 2002

Location: kansas

Posts: 237

Likes: 512

Liked 249 Times in 48 Posts

|

Have a good friend that has built a 1955 Chevrolet to have some fun with. He believes in 3 pedals on the floor and there in lies the problem. He has a total of 2 runs on it and has tore the lining off of the clutch. It's Ram power grip diaphragm clutch recommended by the fine techs at Summit. Who do you recommend he talk to at Ram or McLeod. He's coming back to drag racing after a 40 year lay off and I sure don't want him to get discouraged.

Thanks. Pete I should add that he is running a 350 that is probably making 400 to 425 hp, 4.56 gear and 28x9-15 Mickey Thompson slicks. Last edited by kansas stocker; 06-11-2017 at 11:55 AM. |

|

|

|

|

|

#2 |

|

Junior Member

Join Date: Apr 2016

Posts: 55

Likes: 1

Liked 20 Times in 16 Posts

|

Maybe the clutch wasn't broken in yet, that clutch should be fine at that power level. If the surfaces were freshly machined I could see the organic side pulling loose with too much grip while the metallic side was still slipping.

If it's pretty even 50/50 street strip, I would use that same PP and step up to a 900 series iron disc. Engagement would be a little harsh, but harsh engagement can be mechanically buffered without too much trouble. |

|

|

|

|

|

#3 |

|

Junior Member

Join Date: Apr 2016

Posts: 55

Likes: 1

Liked 20 Times in 16 Posts

|

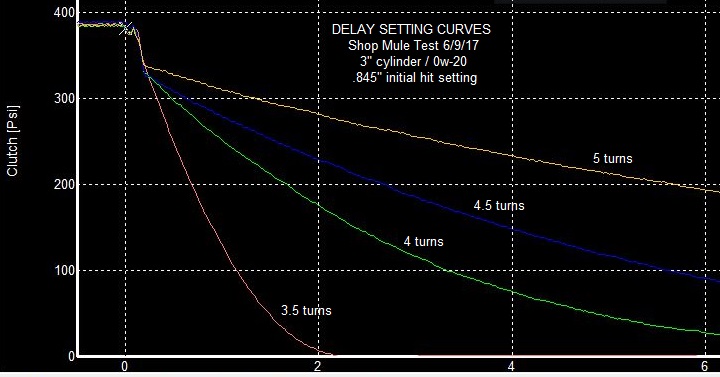

Here's an example of what I mean by a clutch can be mechanically buffered. These are a series of pressure curves from a hydraulic throwout bearing acting against a 2800lb Ram diaphragm PP, buffered with one of my ClutchTamers...

The lines represent different levels of clamp pressure that is initially withheld upon pedal release, then that withheld clamp is allowed to gradually come in at a slower rate. This allows the clutch to hit hard enough to launch the car effectively, but not so hard that the clutch either blows the tires off or causes the engine to bog. Basically it's just a different way to "adjust" a clutch's behavior to find the sweet spot. Here's a graph that shows different rates of feeding in the withheld clamp pressure...  Here's a link to my website that might help explain the concept... http://clutchtamer.com It's pretty easy to build something like this yourself using hardware store materials that might have been available back in the day. Such a scheme might not be in the spirit of a nostalgia racer, but neither will a modern adjustable clutch. Last edited by weedburner; 06-11-2017 at 01:45 PM. |

|

|

|

|

|

#4 | |

|

Veteran Member

Join Date: Mar 2005

Location: Sand Springs, OK

Posts: 8,132

Likes: 896

Liked 390 Times in 170 Posts

|

Quote:

__________________

Ed Wright 4156 SS/JA |

|

|

|

|

|

|

#5 |

|

Senior Member

Join Date: Mar 2006

Posts: 977

Likes: 798

Liked 275 Times in 76 Posts

|

It's probably a good thing the disc is failing otherwise as Ed pointed out the trans or rear end would be hurt. Tim Hyatts son has taken over Hyatt racing clutches since Tim passed away. He would be another place to contact. Whatever you do avoid the mail order places for a performance clutch as it will be a 2000+ pressure plate and a drivetrain killer. A Long style adjustable with lower base and the right disc is what is needed. It does not need to be the latest wiz bang clutch.

Sean

__________________

Sean Marconette 84 Mustang 5060 SS/N |

|

|

|

|

|

#6 |

|

Member

Join Date: Oct 2002

Location: kansas

Posts: 237

Likes: 512

Liked 249 Times in 48 Posts

|

Weedburner was right it ripped the organic material off the face of the clutch disk. He is debating on going with a long style adjustable clutch or using a clutch tamer.

Thanks to all who responded. Said it sure was fun for almost 2 runs. Pete |

|

|

|

|

|

|