Quote:

Originally Posted by Mike Taylor 3601

Thank's Carl

The Dart blocks I have checked with BHJ matched lifter bores great,had some merlins not so great.

Only CNC's I have any info on is I had friend who had a Rottler F-65 could have bought 3 or 4 years ago for 55K wasn't right time for me though and subject came up while talking to Tim at T&S machines, one plus for his machine is all parts are generally available and they have great customer service,I really like my upgrade I got from them for my CWT 3000 balancer.

This is a purchase that will be few years down the road at least if even then.

Mike Taylor 3601

|

Stay away from the knee mills its nothing but a glorified Bridgeport there not that rigid.

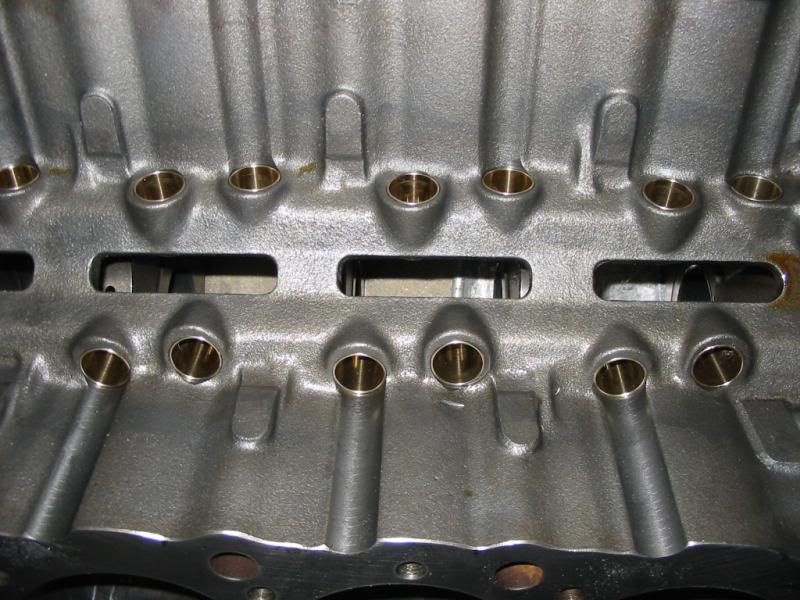

World blocks have a lot of lifter bore issues as I just machine one from .842 to .904 and 4 exhaust bores on the odd side would not clean up. I had to go to 1 inch and install bushings. When the other lifter bores were spot faced they showed they were off.

One World block that came in a few years ago all lifter bores would not clean up from .842 to .904 had to bush them all and just made it a 1 inch on some of them. Customer said the engine never made any power as I can see why. When dealing with roller lifters you dealing with direct center lines If the lifter bores are of any it will change the seat timing events.

Then on some of there blocks they counter bore the lifter bores so deep the lifter bore height is only 1.250 and you have to machine the lifter galley from the deck down to the lifter bore on the exhaust bores.